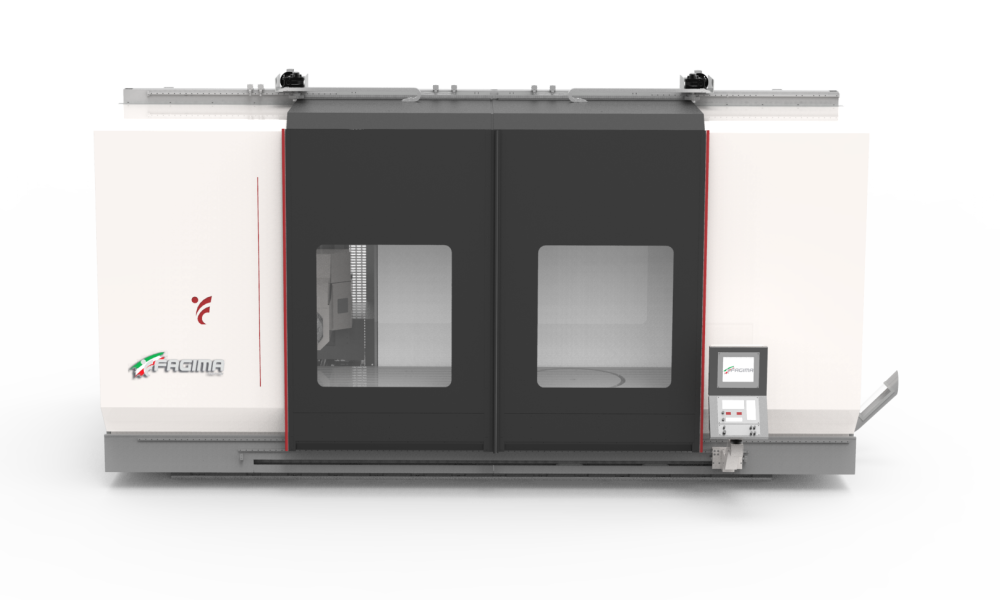

Dominus

/ 3⇢4⇢5 axis machining centers

The Dominus Cnc working center has been designed for a large range of applications, from machining in series to machining of single parts, dies, tools, die templates. The machine design is based on a longitudinal travel with a central fixed table. This design concept guarantees machine stability and accuracy for high milling performance. An appropriate chip evacuator is properly assembled at the end of the fixed table base.

The servo drives combined with ball screws and roller guides ensure high positioning accuracy and a high feed speed. Axis movement is measured by Heidenhain absolute optical scales.

The type of spindle allows machining different types of material, including light metal alloys or very hard steel alloys. The field of application ranges from aerospace, maritime and energy to the mechanical sector in general. Cnc working center are machine tools whose movements are controlled by an electronic device integrated in the machine called numerical control. The movements and functions of these machines are predetermined, ie they are pre-set at the table through specific software.